Coating and printing of drill holes with pad printing

VARIOPRINT optimises the coating of drill holes

In order to be able to coat even complex inner geometries, VARIOPRINT has developed new system solutions on the basis of the pad printing method. With these, drill holes can be precisely coated with solid film lubricants, release agents, oil, adhesives, paints, etc.

An expandable pad roll is mounted on a rotatable pin, which is mounted on the pad axle of an electrically driven VARIOPRINT pad printing machine. The circumference and width of the drill hole to be printed has been evenly applied to the printing block.

With the printing process, the printing pin is applied parallel on the printing block, after this, the printing block proceeds such that the printing pin rotates on the printing block and the printing surface is transferred to the pad roll. Now, the printing pin moves into the drill hole to be printed. The pad roll is expanded. The printing medium is transferred into the drill hole.

Product flyer coating of drill holes:

- No spraying, no contamination outside of the coating area

- Even layer thickness across the entire depth of the drill hole

- Precise transferring

- Lubrication assistance with thermal stress

For this, solid film lubricants are applied, e.g. with piston pin drill holes – with very high precision of layer thickness - Bushing assembly, optimisation of pressing characteristic

Application of lubricant (wax) in the printing area of drill holes. Through the high application precision, the subsequent welding of assembly parts is not impaired. - The seating points of plastic housings of electrical devices can be printed with solid film lubricants (saving of bearing bushings).

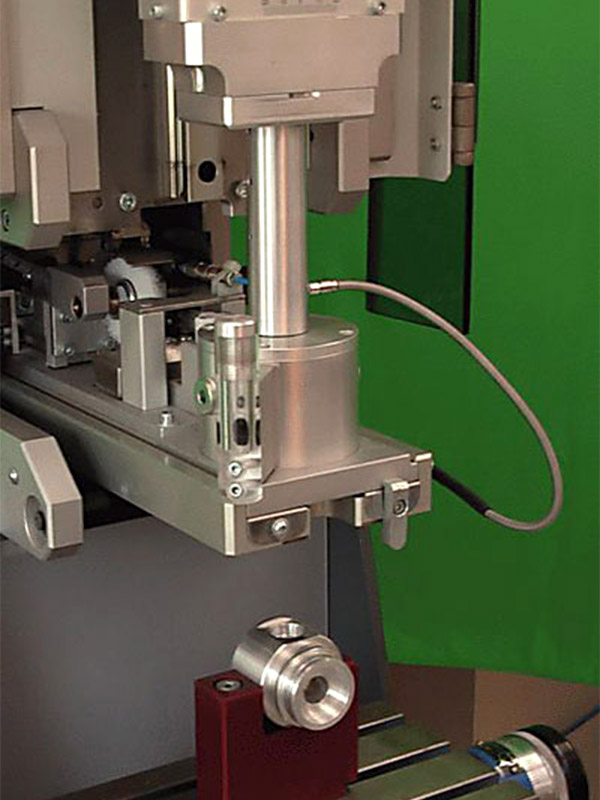

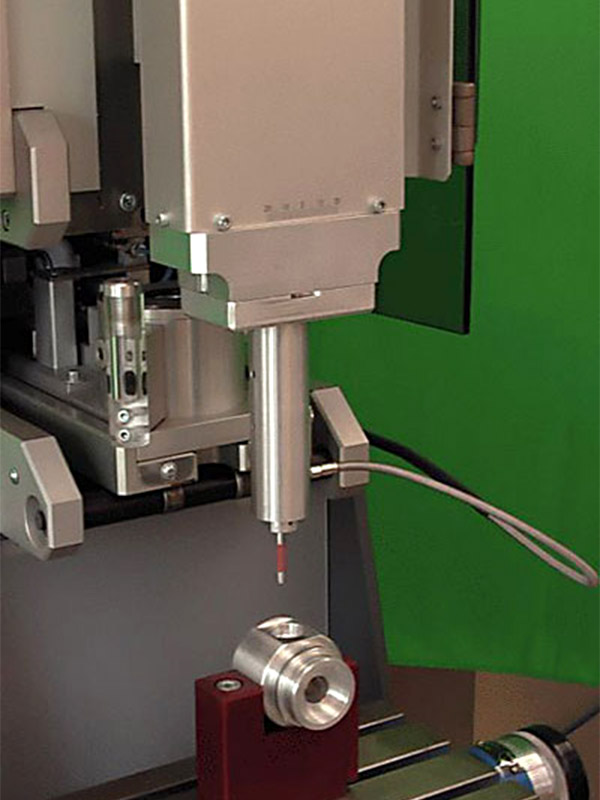

Printing pin

Coating of deep drill holes with small diameter

Application example:

Drill hole with a 5 mm diameter is coated with lubricant at a depth of 15 mm:

Printing pin, immersed in the medium reservoir

Printing pin prior to immersion in the printed part

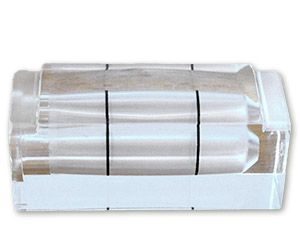

Hat pad

Coating of drill holes

VARIOPRINT Patent No. 10 2008 015 641

VARIOPRINT hat pad systems allow the precise coating of drill holes with a depth/diameter ratio of approx. 1:1.

Application example:

A drill hole with a diameter of 15 mm is coated with lubricant to a depth of 13 mm.

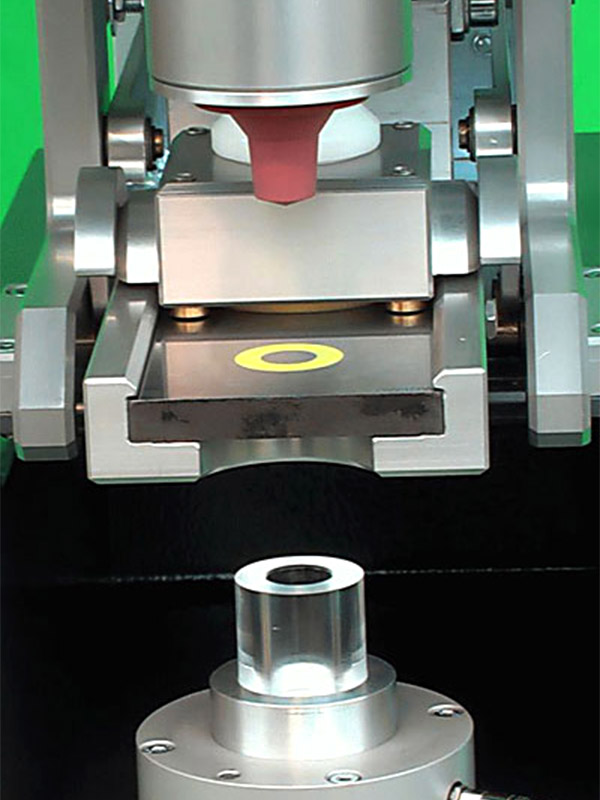

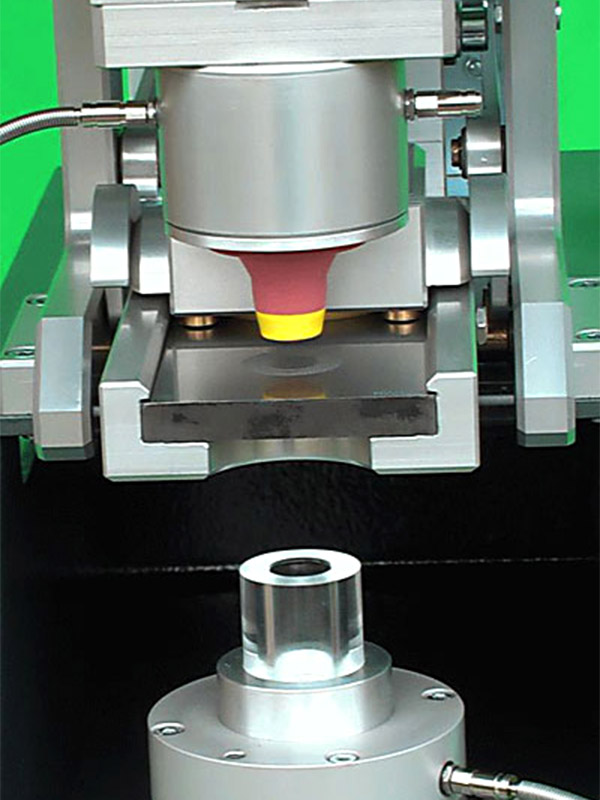

Printing block moves over the hat pad. The coating medium is provided in the required layer thickness.

In an inflated condition, the hat pad moves onto the printing block and takes the coating medium

Hat pad moves into the drill hole to be coated and passes the coating medium on to the drilling wall through expansion

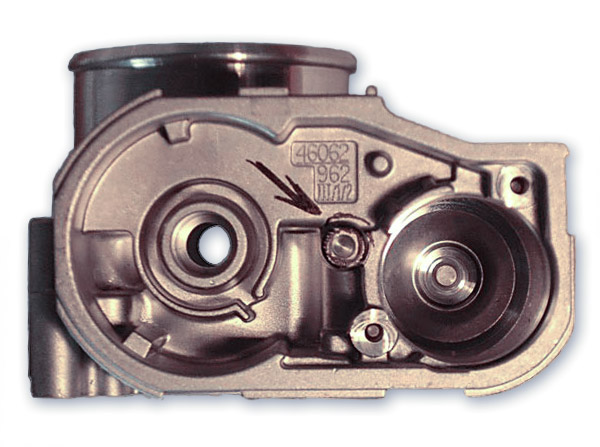

Print roll

Coating of drill holes

VARIOPRINT Patent No. 102 42 489

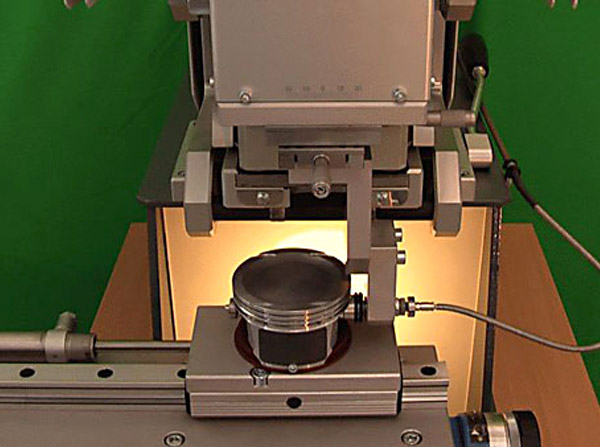

VARIOPRINT print roll systems for coating drill holes with high-precision layer thickness.

Application example:

Solid film lubricant is transferred into the printing area of the piston pin drill hole with very high-precision layer thickness.

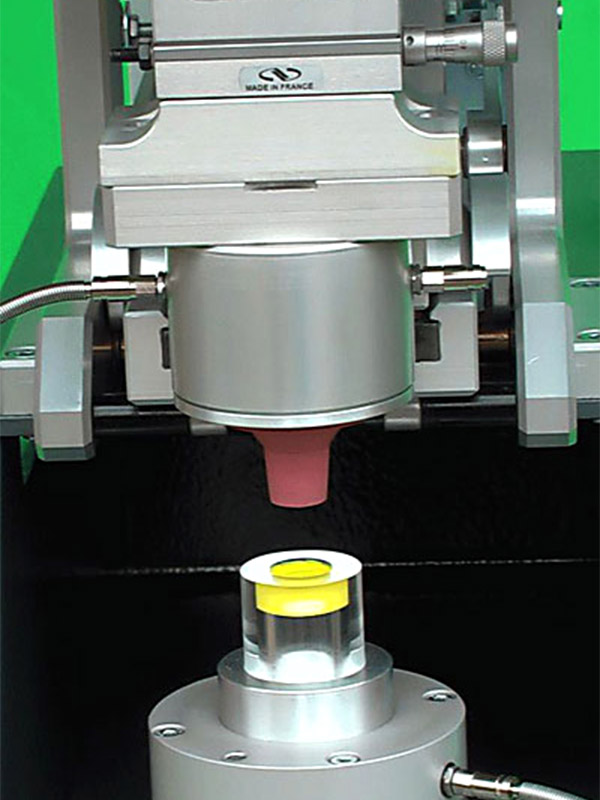

Print roll takes the print medium from the printing block in linear form

The print roll moves to the transfer position with the print medium.

The print part moves into the print roll with the drill hole to be coated. The print roll transfers the print medium to the drill hole wall by expanding.

Inner cone:

Leveling: